What’s the Best Torque Wrench for Dirt Bikes and Motorcycles?

BraapAcademy.com earns a small commission from qualifying purchases.

This does NOT cost you extra.

Contents

I can’t tell you how many bolts I’ve stripped. You’ve probably stripped one or two out as well. And if you haven’t – good job. There are too many stories of oil drain bolts snapping or spark plugs being over-tightened, all because someone was working on a dirt bike without a torque wrench. But I’m not telling you something you don’t already know. After all, that’s why (probably) you’re reading this page.

Below is my “best torque wrench” recommendation for motorcycles and dirt bikes.

While I wish that there was a one-size-fits-all torque wrench, there really isn’t. Picking a torque wrench based on what you need it for, or plan on using it for is the best approach. In a perfect world, you’d actually have two or three different torque wrenches. I’ll explain.

My Dirt Bike Torque Wrench Recommendation

I’ve picked two different wrenches.

One is a 1/4 inch analog torque wrench, and the other is a 3/8 inch digital torque wrench.

I’ll explain below why these two are the ones I like and recommend.

1/4 Inch – Best Analog Torque Wrench

TEKTON TRQ21101 1/4-Inch Drive Dual-Direction Click Torque Wrench (10-150 in.-lb./1.1-16.9 Nm)

I like the Tekton for a few reasons:

- Easy-to-use click-style wrench

- Great torque setting ranges for working on a dirt bike

- Fairly accurate

- Reversible

View and read reviews on Amazon

3/8 Inch – Best Digital Torque Wrench

No products found.

Craftsman 3/8-in. Dr. Digi-click Torque Wrench, 5-80 Ft. Lbs.

I like this one for a few reasons:

- Quality, Craftsman name, and build

- Best range for working on dirt bikes – 5-80 ft. lbs.

- Convert from ft. lbs. to in. lbs., etc. with a push of a button

- Nice LED, digital screen

No products found.

What Makes a Good Dirt Bike Torque Wrench

As with everything, there are going to be trade-offs no matter what you go with. Here are a few of the important things to look for, in my opinion, because you want to choose the best torque wrench for your dirt bike.

- Available torque settings.

The torque specs of a car can be quite a bit different than those of a dirt bike. The most common settings you’ll probably be using the torque wrench for are about 5-20 ft. lbs. As you can see below, the lowest is 1.1 ft. lbs., whereas the highest is 94 ft. lbs. Both of those extremes are the exception; not the norm. - Drive size.

As discussed in more detail below, the size you choose is very important. Unfortunately, you won’t be able to make every adjustment with just one size. So pick wisely… or get two. - Accuracy & fine-tuning.

If you’ve looked at your manual you may have noticed that some of the settings are quite specific. Some read 1.1 ft. lbs. while some read 2.7 ft. lbs. Depending on your needs and requirements, you may want a torque wrench that has settings to the tenth of a pound. - Quality and durability.

Let’s admit one thing now – riding and maintaining a dirt bike is not a cheap hobby, and buying a good torque wrench is not where you should be looking to pinch any pennies. Save yourself the headache (and money in the long run) and don’t buy some cheap Harbor Freight torque wrench.

In addition to the above, you’ll also be choosing the display type. Some torque wrenches have a digital reading while others are analog. Personally, I like the digital reading a little more because they are easier to be more precise with, and they are more accurate on the upper and lower scales. But like I said, there is a trade-off to a digital torque wrench: price. As in, not cheap. Also, let’s be real; The analog works just fine.

What Size Torque Wrench?

This is one of the more important things to consider. If you’re looking to be able to torque the majority of nuts and bolts on your dirt bike, then you’re probably going to want to go with a 1/4 inch torque wrench because this is what the majority of maintenance items call for.

Ideally, you’d actually get a 1/4 inch and No products found. wrench, but to start, I’d recommend at least getting a 1/4″ wrench.

Having a 1/4″ torque wrench will allow you to tighten most of the motor/engine bolts. Once you start getting into the suspension bolts and some of the other, larger engine bolts, you’ll need a 3/8″ torque wrench.

Types of Torque Wrenches

There are quite a few different types of torque wrenches. However, not all would be a good choice for working on a motorcycle. Here’s a list of the different types that I got from Wikipedia:

- Beam

- Deflecting beam

- Slipper

- Click

- “No-hub” wrench

- Electronic torque wrenches

- Programmable electronic torque / angle wrenches

- Mechatronic torque wrenches

- Hydraulic torque wrenches

That’s a lot!

These all have their own pros and cons. As a result, they work slightly different from each other. I won’t get into what each one is/isn’t because it really doesn’t matter.

The most common, or at least well-known and recognized, are probably the Beam, Click and Hydraulic torque wrenches.

The beam wrench is one I would recommend you avoid. These are typical of lower quality. The beam torque wrench has a needle (or beam) that points to the amount of torque. These can also be more difficult to read and are not as accurate in lower torque settings.

A “click” wrench is designed to slip (or click) once you reach the level of torque that you set it to. This is a very common method and helps prevent over-tightening or stripping.

The hydraulic torque wrench is definitely not designed for a dirt bike. These are the bigger, more powerful wrenches that are used on cars.

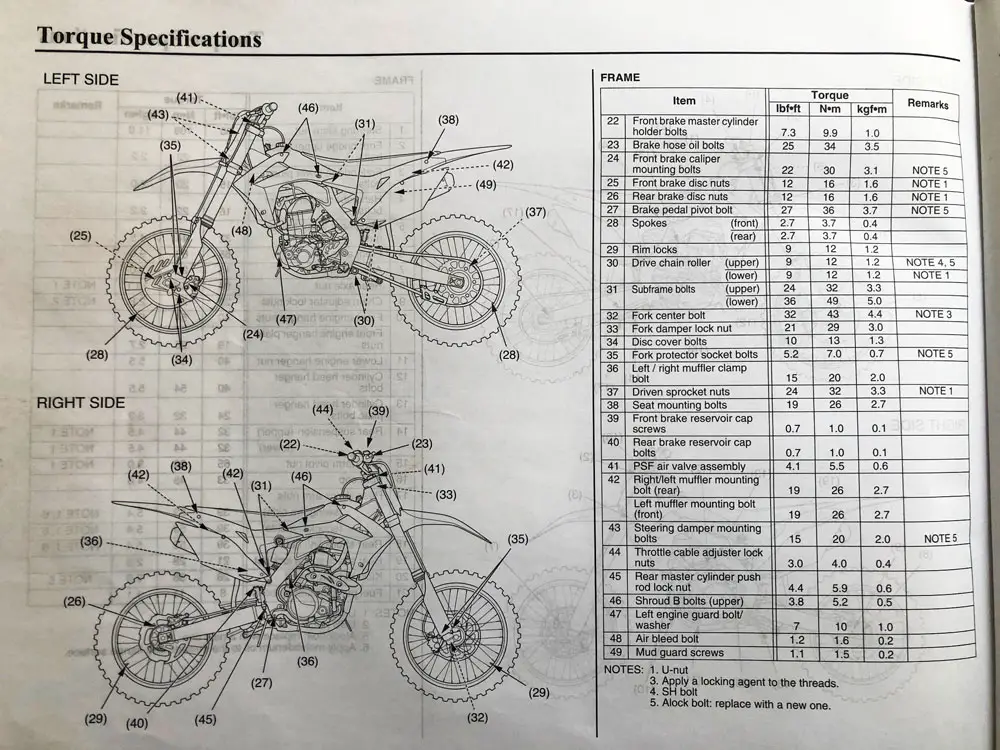

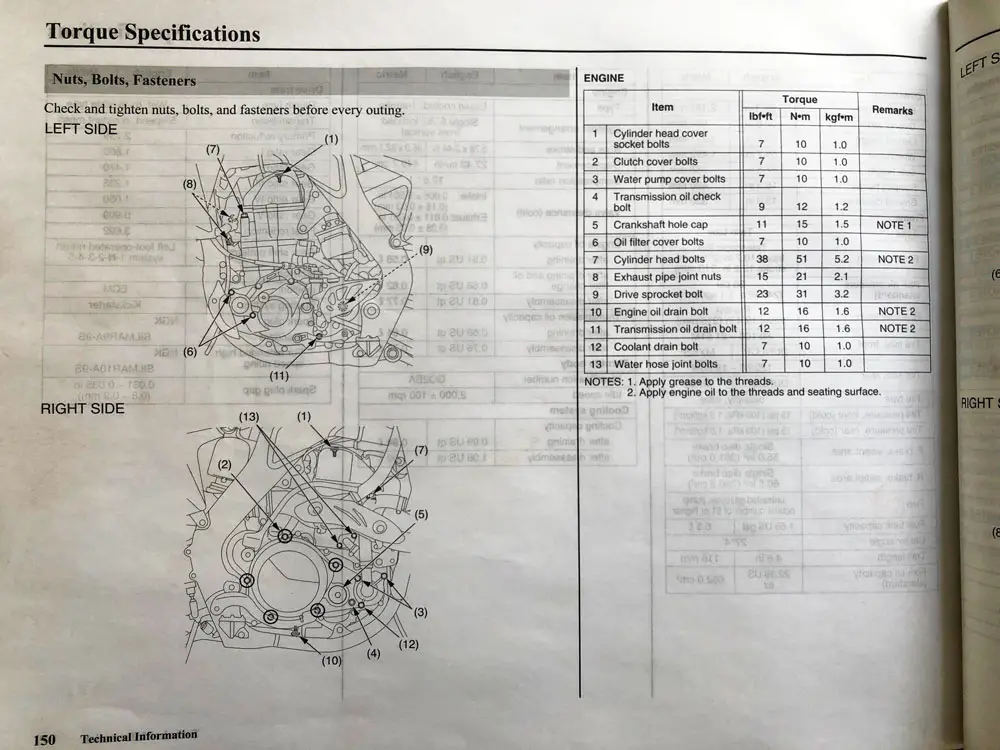

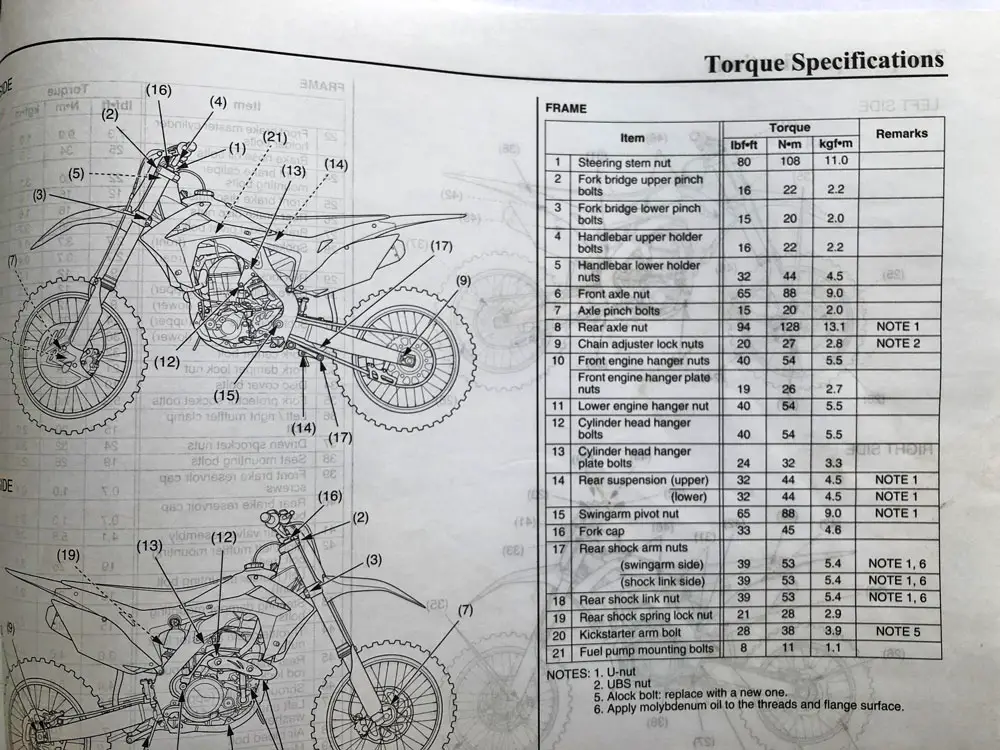

Torque Specs

Here are the torque specifications and photos from my owner’s manual. I’ve got a 2015 Honda CRF450R. I’m not sure how much the torque specs change from one bike to another, but I doubt that they’re much different. A little different, most likely. But not a whole lot.

As you’ll see, the majority of the specs call for about 20 ft. lbs.

With the exception of the Steering Stem Nut (80 ft. lbs.) and the Rear Axle Nut (94 ft. lbs.), 65 ft. lbs. is as high as it goes.

The lowest setting is 1.1 ft. lbs., however, there are a large number of bolts that call for ~7 ft. lbs.

Engine Torque Specifications

- Cylinder head cover socket bolts – 7 ft. lbs.

- Clutch cover bolts – 7 ft. lbs.

- Water pump cover bolts – 7 ft. lbs.

- Transmission oil check bolt – 9 ft. lbs.

- Crankshaft hole cap – 11 ft. lbs.

- Oil filter cover bolts – 7 ft. lbs.

- Cylinder head bolts – 38 ft. lbs.

- Exhaust pipe joint nuts – 15 ft. lbs.

- Drive sprocket bolt – 23 ft. lbs.

- Engine oil drain bolt – 12 ft. lbs.

- Transmission oil drain bolt – 12 ft. lbs.

- Coolant drain bolt – 7 ft. lbs.

- Water hose joint bolts – 7 ft. lbs.

Frame Torque Specifications

- Steering stem nut – 80 ft. lbs.

- Fork bridge upper pinch bolts – 16 ft. lbs.

- Fork bridge lower pinch bolts – 15 ft. lbs.

- Handlebar upper holder bolts – 16 ft. lbs.

- Handlebar lower holder nuts – 32 ft. lbs.

- Front axle nut – 65 ft. lbs.

- Axle pinch bolts – 15 ft. lbs.

- Rear axle nut – 94 ft. lbs.

- Chain adjuster lock nuts – 20 ft. lbs.

- Front engine hanger nuts – 40 ft. lbs.

Front engine hanger plate nuts – 19 ft. lbs. - Lower engine hanger nut – 40 ft. lbs.

- Cylinder head hanger bolts – 40 ft. lbs.

- Cylinder head hanger plate bolts – 24 ft. lbs.

- Rear suspension upper – 32 ft. lbs.

Rear suspension lower – 32 ft. lbs. - Swingarm pivot nut – 65 ft. lbs.

- Fork cap – 33 ft. lbs.

- Swingarm side – Rear shock arm nuts – 39 ft. lbs.

Shock link side – Rear shock arm nuts – 39 ft. lbs. - Rear shock link nut – 39 ft. lbs.

- Rear shock spring lock nut – 21 ft. lbs.

- Kickstarter arm bolt – 28 ft. lbs.

- Fuel pump mounting bolts – 8 ft. lbs.

- Front brake master cylinder holder bolts – 7.3 ft. lbs.

- Brake hose oil bolts – 25 ft. lbs.

- Front brake caliper mounting bolts – 22 ft. lbs.

- Front brake disc nuts – 12 ft. lbs.

- Rear brake disc nuts – 12 ft. lbs.

- Brake pedal pivot bolt – 27 ft. lbs.

- Spokes (front) – 2.7 ft. lbs.

Spokes (rear) 2.7 ft. lbs. - Rim locks – 9 ft. lbs.

- Drive chain roller (upper) – 9 ft. lbs.

Drive chain roller (lower) – 9 ft. lbs. - Upper subframe bolts – 24 ft. lbs.

Lower subframe bolts – 36 ft. lbs. - Fork center bolt – 32 ft. lbs.

- Fork damper lock nut – 21 ft. lbs.

- Disc cover bolts – 10 ft. lbs.

- Fork protector socket bolts – 5.2 ft. lbs.

- Left / right muffler clamp bolt – 15 ft. lbs.

- Driven sprocket nuts – 24 ft. lbs.

- Sear mounting bolts – 19 ft. lbs.

- Front brake reservoir cap screws – 0.7 ft. lbs.

- Rear brake reservoir cap bolts – 0.7 ft. lbs.

- PSF air valve assembly – 4.1 ft. lbs.

- Right / left muffler mounting bolt (rear) – 19 ft. lbs.

Left muffler mounting bolt (front) – 19 ft. lbs. - Steering damper mounting bolts – 15 ft. lbs.

- Throttle cable adjuster lock nuts – 3 ft. lbs.

- Rear master cylinder push rock lock nut – 4.4 ft. lbs.

- Shroud B bolts (upper) – 3.8 ft. lbs.

- Left engine guard bolt/washer – 7 ft. lbs.

- Air bleed bolt – 1.2 ft. lbs.

- Mud guard screws – 1.1 ft. lbs.

Should I Buy a Torque Wrench for My Dirt Bike?

In a word? Yes.

Using a torque wrench to work on a dirt bike is a good idea. Not only does it take the guess-work out of how tight you should crank on a bolt, but it but it will also save you a lot of headaches. If you end up stripping or snapping just one or two bolts while changing your oil (or any other task), you are going to wish you had been using a torque wrench… and you may end up going out and buying one after the fact.

Because whether you choose a digital or analog torque wrench doesn’t matter a whole lot in the end, it’s mostly going to come down to your personal preference. The important thing is that you’ve got one and you’re using it. I recommend looking at both of the recommendations above (the 1/4 inch torque wrench and the No products found.) and either pick up one or both of them.

You won’t regret it.